2-in-1 Material Rack Correction Machine Market to Reach USD 477.9 Million by 2035, Driven by Lean Automation

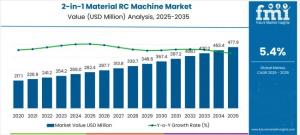

Global 2-in-1 Material Rack Correction Machine Market to hit USD 477.9 Million by 2035, growing at 5.4% CAGR on rising automation and space optimization.

NEWARK, DE, UNITED STATES, November 10, 2025 /EINPresswire.com/ -- The global 2-in-1 material rack correction machine market is on a steady upward trajectory, expected to grow from USD 282.4 million in 2025 to USD 477.9 million by 2035, reflecting an absolute gain of USD 195.5 million and an overall expansion of 69.3%. This growth represents a CAGR of 5.4% over the forecast period, underscoring increasing demand for multi-functional, space-saving industrial equipment designed for modern manufacturing environments.

The surge in adoption of 2-in-1 material rack correction machines is being driven by manufacturing facilities’ shift toward lean production, operational versatility, and space optimization. As industrial real estate becomes more constrained and expensive, industries are prioritizing equipment that combines dual functionality with compact design—reducing both the equipment footprint and maintenance downtime.

Asia Pacific Leads the Global Growth Curve

The Asia Pacific region remains the powerhouse of global growth, supported by strong manufacturing bases in China, India, and Southeast Asia. China alone is expected to post a 7.3% CAGR, the highest globally, powered by large-scale investments in automation and industrial modernization. India follows closely with 6.8% CAGR, reflecting growth in automotive and logistics infrastructure.

In Europe, Germany leads the market, posting 6.2% CAGR owing to its advanced automotive and machinery manufacturing sectors. Meanwhile, North America—led by the United States—records steady growth at 5.1% CAGR, supported by the rise of smart factories and robotics-based production facilities.

By 2035, Asia Pacific is expected to account for nearly 45% of the total global revenue, followed by Europe at 27% and North America at 20%, as global industries embrace dual-function precision systems for process efficiency and layout optimization.

Market Composition and Functional Importance

Within the industrial machinery ecosystem, 2-in-1 material rack correction machines play a pivotal role in enhancing productivity and maintaining alignment accuracy across diverse applications such as metal processing, automotive manufacturing, and electronics production.

By segment contribution:

- Industrial Machinery: 7.4% market share

- Material Handling Equipment: 9.2%

- Manufacturing Automation: 8.1%

- Packaging Machinery: 6.5%

- Factory Automation Systems: 7.8%

Together, these segments account for nearly 39% of total parent market integration, illustrating how 2-in-1 systems have become a core operational element in automated production ecosystems.

Dominant Segments and Emerging Opportunities

The hand-crank expansion mechanism continues to dominate the market, offering precise manual control and cost-effective implementation. This segment alone contributes USD 70–90 million in potential revenue, favored for its reliability and high precision in manual production settings.

The hydraulic and automated expansion segment, valued at USD 60–80 million, is gaining traction in advanced production lines, while the smart multi-axis positioning systems are forecasted to contribute USD 40–60 million, reflecting rising adoption of AI-based synchronization and adaptive motion control.

By application, metal processing leads with the largest market share in 2025, as steel, sheet metal, and fabrication industries increasingly demand dual-function correction systems to streamline high-throughput manufacturing. Meanwhile, automotive and electronics sectors are embracing these machines to achieve production versatility, layout efficiency, and improved alignment accuracy.

Regional Insights: Market Hotspots

- China: Leads the global market with 7.3% CAGR, driven by smart manufacturing and infrastructure investments.

- India: Expands at 6.8% CAGR, backed by logistics sector modernization and Make-in-India manufacturing initiatives.

- Germany: Records 6.2% CAGR, powered by Industry 4.0 integration and advanced automation systems.

- Brazil: Grows at 5.7% CAGR as industrial facilities invest in space-efficient automation.

- USA: Maintains 5.1% CAGR, with growth led by robotics, e-commerce logistics, and warehouse automation.

- UK and Japan: Record 4.6% and 4.1% CAGR respectively, driven by operational efficiency and sustainability initiatives.

Key Market Drivers and Trends

The growth momentum is being reinforced by three key industry shifts:

- Lean Manufacturing Adoption: Companies are optimizing their production floors to reduce redundancy by integrating multi-function machines that handle both material storage and correction in one compact unit.

- Automation and Smart Control Integration: Intelligent dual-function automation with synchronized control systems enhances process accuracy, reducing human intervention and cycle time.

- Sustainability and Modular Design: The next generation of machines emphasizes energy efficiency, modular construction, and easy retrofitting—aligning with global ESG and circular economy goals.

Explore the full market insights and future trends—read the complete Market Report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-26362

Buy Now Report Here: https://www.futuremarketinsights.com/checkout/26362

Competitive Landscape

The market features both global industrial giants and regionally specialized automation providers. Leading manufacturers include Mahlo GmbH + Co. KG, Ideal Machine, GESCO-Group, Shung Dar, Shanghai Wansheng Machinery Automation, and Lihao Machine. These companies are focusing on precision engineering, intelligent control systems, and integrated dual-function technologies to expand their global footprint.

Emerging players such as Qingdao Yituo Machinery Equipment, Hebei Zhijie Machinery Manufacturing, and Kunshan Longgengkai Mechanical Equipment are targeting cost-sensitive markets through innovation in manual precision and compact modular systems.

Outlook 2035: Smart Integration and Regional Expansion

As global industries accelerate their transition toward automation, space efficiency, and synchronized material flow, the 2-in-1 material rack correction machine stands at the forefront of manufacturing transformation. The technology’s ability to integrate dual correction functions, minimize space usage, and enhance process flexibility positions it as a cornerstone of modern smart factories.

By 2035, the market’s projected value of USD 477.9 million signifies not just growth in machinery but a broader shift in industrial design philosophy—from standalone operations to integrated, multi-functional, and intelligent production systems.

Related Reports:

Power Generator for Military Market- https://www.futuremarketinsights.com/reports/power-generator-for-military-market

Aerospace Valves Market- https://www.futuremarketinsights.com/reports/aerospace-valves-market

Power System Simulator Market- https://www.futuremarketinsights.com/reports/power-system-simulator-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.